Swipe left or right to close the panel.

×

Top 10 Most Related Posts

Best Review Based on Most Mentioned Phrase / Active User

Suppliers Pressure Die Casting

5 times mentioned • Masha K • 07 August 2017

Suppliers Pressure Die Casting

|

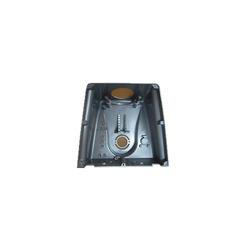

We are successful manufacturers, exporters, traders and suppliers of Pressure Die Casting and have never failed our customers on the aspects such as durability, design and patterns. Further, these dies are fabricated at our state-of-the-art manufacturing unit under the guidance of our qualified professionals using the finest quality raw material and advanced technology. Tested against various quality parameters, we offer them at most reasonable prices.

|

|

Suppliers Pressure Die Casting

5 times mentioned • Masha K • 07 August 2017

Suppliers Pressure Die Casting

|

We are successful manufacturers, exporters, traders and suppliers of Pressure Die Casting and have never failed our customers on the aspects such as durability, design and patterns. The ejector die contains the ejector pins and usually the runner, which is the path from the sprue or shot hole to the mould cavity. The cover die is secured to the stationary, or front, platen of the casting machine, while the ejector die is attached to the movable platen. The mould cavity is cut into two cavity inserts, which are separate pieces that can be replaced relatively easily and bolt into the die halves.

|

|

Suppliers Pressure Die Casting

5 times mentioned • Masha K • 07 August 2017

Suppliers Pressure Die Casting

|

We are successful manufacturers, exporters, traders and suppliers of Pressure Die Casting and have never failed our customers on the aspects such as durability, design and patterns. This one relies upon a pool of molten metal to feed the die. At the beginning of the cycle the piston of the machine is retracted, which allows the molten metal to fill the gooseneck. The pneumatic or hydraulic powered piston then forces this metal out of the gooseneck into the die.

|

|

Never Failed Customers The Aspects

4 times mentioned • Bob Chen • 07 August 2017

Never Failed Customers The Aspects

|

We are successful providers of Powder Coating Services and have never failed our customers on the aspects such as durability, design and patterns. There is often a scenario where corrosion and rust cause a huge amount of damage to the goods. We provide these services in order to protect the tools and components from external damaging factors and also provide an insight in to which coating to choose for which particular product. To assure the required level of coating instruments like Coat thickness meter, Chrominance meter, Gloss meter are used.

|

|

Suppliers Pressure Die Casting

5 times mentioned • Masha K • 07 August 2017

Suppliers Pressure Die Casting

|

Our company has earned great laurels as manufacturers, traders and suppliers of Pressure Die Casting in the market at present. These are used when the casting alloy cannot be used in hot-chamber machines; these include aluminium, zinc alloys with a large composition of aluminium, magnesium and copper. The process for these machines start with melting the metal in a separate furnace.

|

|

Suppliers Pressure Die Casting

5 times mentioned • Masha K • 07 August 2017

Suppliers Pressure Die Casting

|

Our company has earned great laurels as manufacturers, traders and suppliers of Pressure Die Casting in the market at present. The metal is forced into a high grade steel tool at high speed and -pressure. The casting temperature is roughly 700°C during casting. The use of vacuum casting technology is an advantage in order to achieve superior quality for light and thin walled components. On-time delivery is something that we always promise and maintain.

|

|

Quality Management System

30 times mentioned • Edison Leo • 09 November 2017

Quality Management System

|

OKA currently operates three batching plants in the factory for the production of readymixed concrete for in-house usage and commercial supply. OKA utilize the finest quality of raw materials obtained from Kinta Valley and with our ISO 9001 quality management system, the quality of the readymixed concrete produced are being constantly monitored. The readymixed concrete grades that OKA produces range from Grade 10 to Grade 60. Special design readymixed concrete can also be produced according to the customers' specification.

|

|

High Quality Product

24 times mentioned • Rachel Lim • 28 August 2020

High Quality Product

|

Serta Mattresses is made from top quality raw materials imported from quality conscious European and American markets. Finest quality of raw material is imported from across the globe for manufacturing superior and high quality product. All the chemicals for manufacturing mega foam and visco gel foam are imported from Germany. Complete range of fabric namely fire retardant fabric, nanotex fabric, anti-allergic, medicated fabrics etc. are imported from Belgium.

|

|

Using The Finest Quality

5 times mentioned • Abu Bakar • 28 February 2018

Using The Finest Quality

|

For those who seek the finest in bed linens, Grand Atelier is the preferred bed and bath brand with its reputation for quality, comfort and beautiful design.

All Grand Atelier bed and bath products have been designed and made using the finest quality materials available, resulting in luxurious and classic linens that will not only complement the beautiful interiors of your bedroom, but more importantly, promise you with a relaxing and rejuvenating night's sleep. As always at Grand Atelier, fine living is all about the details.

|

|

Using The Finest Quality

5 times mentioned • Kenny Chin • 13 February 2018

Using The Finest Quality

|

Key features of our Luxury range include exotic fibre blends, natural latex, Australian-made, locally sourced materials, hand-selected to suit comfort levels, durability, guarantees of up to 10 years on beds and 5 years on bedroom furniture. Design your dream retreat

When it comes to bedroom furniture, our Australian-made pieces are built to last for generations. Using the finest quality hardwoods such as Victorian Ash and Tasmanian Oak, they're meticulously handmade using craftsmen techniques.

|

|

Everyone can have their own blog websites now. People use Invaber to blog their life, post their wishlists, post their preferences, share with others on Google. You also can discover more on what you blog. Invaber is sponsored by Microsoft.

|

|

Join Invaber |

|

|

What is Invaber? |

|

Lastest Business

|

|