Swipe left or right to close the panel.

×

Die Casting

Best Review Based on Most Mentioned Phrase / Active User

Company Has Established Name Strongly

8 times mentioned • Masha K • 07 August 2017

Company Has Established Name Strongly

|

As a prime manufacturer, trader and supplier of Pressure Die Casting, our company has established its name very strongly in the market. The cover die contains the sprue (for hot-chamber machines) or shot hole (for cold-chamber machines), which allows the molten metal to flow into the dies; this feature matches up with the injector nozzle on the hot-chamber machines or the shot chamber in the cold-chamber machines.

|

|

Forcing Molten Metal Under High

4 times mentioned • Gohan Goku • 09 October 2017

Forcing Molten Metal Under High

|

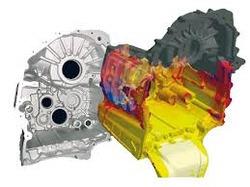

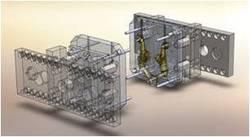

Aluminium Die Casting Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity.Die design The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Die design

|

|

Zinc High Pressure Die Castings

4 times mentioned • Masha K • 07 August 2017

Zinc High Pressure Die Castings

|

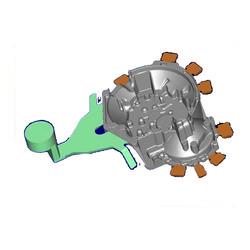

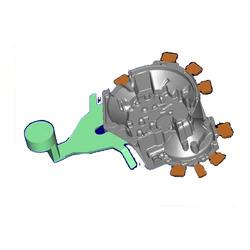

Alongside our aluminium and zinc high pressure die castings, we offer High Pressure Die Casting bespoke design service that is tailored to your specific needs. Our talented design team will work with you every step of the way from the design stages of an aluminium and zinc casting to the finished product. We work hard to ensure that you receive aluminium and zinc castings of the highest quality, at a price that works for both parties through continuous stringent value engineered cost reductions.

|

|

Company Has Earned Great Laurels

4 times mentioned • Jayden Lee • 07 August 2017

Company Has Earned Great Laurels

|

Our company has earned great laurels as manufacturers, traders and suppliers of Zinc Die Casting in the market at present. The main function of this particular group of metals is to improve machinability. We use mainly alloys of zinc, because these alloys have good ductile and malleability properties. They are known for their resistance towards corrosion and abrasion and their long service life. Common applications include connectors for wire and cable, electrical plug type connectors, door knobs, screws and nuts, bushings for corrosion, rolling mill bearings, and many more.

|

|

Die Casting Produces Highly Repeatable

3 times mentioned • Mandy B B • 07 September 2017

Die Casting Produces Highly Repeatable

|

Rheocast specializes in cold chamber machine high-pressure brass die casting. In cold chamber die casting, a precise amount of molten metal is fed into a "cold chamber" where a hydraulic plunger forces the metal into a sealed die at high-pressures. High-pressure brass die casting produces highly repeatable, complexshapes at competitive prices. Advantages of brass die cast components include corrosion resistance, even in salt water applications and xtreme temperature-resistance, even in a burning building.

|

|

Custom Motorcycle Parts Small Metal

3 times mentioned • Mandy B B • 23 August 2017

Custom Motorcycle Parts Small Metal

|

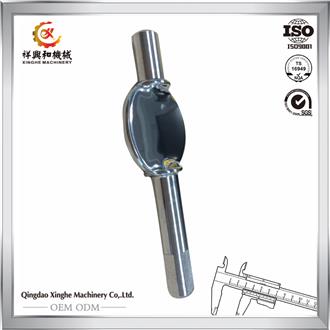

Custom motorcycle parts small metal part sheet metal fabricator. We has over 20 years experiences in high precision stamping parts, deep drawing part, welding and die casting parts, for a wide range of industry sectors, which used for electrical, electronic, automotive, medical equipment, solar energy, etc.

230 workers, 60000 ㎡ workshop, 12 years experience, 3 years' vendor of Webasto and Siemens, ISO,CE, ROHS, SGS certificated, three hour reach Tianjin port, this is how we keep superior quality and competitive offers for global valued customer

|

|

Molten Material Poured Mould Duplicate

3 times mentioned • Masha K • 07 August 2017

Molten Material Poured Mould Duplicate

|

We manufacture, trade and supply a wide variety of Pressure Die Casting. Molten material is poured into a mould to duplicate a desired pattern. It includes is a manufacturing process in which molten metal (aluminium) is injected with a die casting machine under force using considerable pressure into a steel mould or die to form products. These are made available to the customers at extremely affordable rates.

|

|

High Quality Raw Materials

7 times mentioned • Kenny Chin • 07 August 2017

High Quality Raw Materials

|

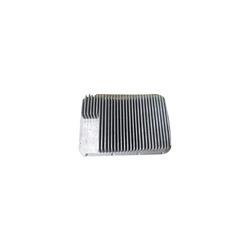

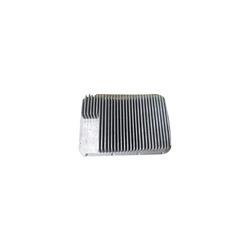

This is a pressure die casting machine is basically designed for the power industries. In general Power Coated Heat Sink machine is workable in the manufacturing industries of electrical devices includes TV, computer, LCD, LED and lighting components. Our product is durable as we are including high quality raw materials in the manufacture.

|

|

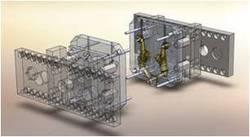

High Pressure Die Casting

6 times mentioned • Mandy B B • 07 September 2017

High Pressure Die Casting

|

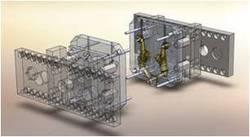

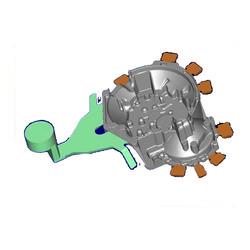

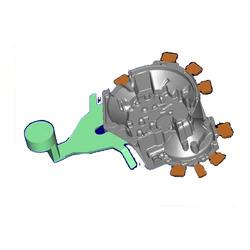

Our products are mainly used in valve industries.We can provide many kinds of casting parts/stamping parts/machining parts and forging parts. Aluminum casting, sand casting, die casting, gravity casting, high pressure die casting, low pressure die casting, forging, stamping, machining. Applied software for specification drawings: Auto CAD, Solidworks. Precision machining: CNC, milling machine, drilling machine, numerical lathe, all types of lathe. Surface finish process: polishing, sand blasting, heat treatment, painting and powder coating.

|

|

Suppliers Pressure Die Casting

5 times mentioned • Masha K • 07 August 2017

Suppliers Pressure Die Casting

|

We are successful manufacturers, exporters, traders and suppliers of Pressure Die Casting and have never failed our customers on the aspects such as durability, design and patterns. The ejector die contains the ejector pins and usually the runner, which is the path from the sprue or shot hole to the mould cavity. The cover die is secured to the stationary, or front, platen of the casting machine, while the ejector die is attached to the movable platen. The mould cavity is cut into two cavity inserts, which are separate pieces that can be replaced relatively easily and bolt into the die halves.

|

|

Wide Range Products Includes

4 times mentioned • Kenny Chin • 07 August 2017

Wide Range Products Includes

|

Our wide range of products includes Pressure Die Casting for Power Industry which has very good demand in the market for its utility. The optimum quality materials are used in the manufacturing of these pressure die castings which ensures their long lasting and flawless performance. This is a die casting tool is workable for the power industries. The working strategy of Pressure Die Casting for Power Industry is based on high pressure. Our product is durable and offering more efficiency limit.

|

|

Components Die Casting Mould

4 times mentioned • Rayden Khoo • 31 July 2017

Components Die Casting Mould

|

Quality Assurance Aluminum/Zinc/Magnesium Machine Parts die casting mold maker. Auto components die casting mould and part company housinging mould. Communication components die casting mould and part company housinging mould. Machine components die casting mould and part company housinging mould. Door/window/furniture components die casting mould and part company housinging mould. Furniture hardware fittings, Industrial hardwares, Lights & lamps parts, etc.

|

|

Aluminium Die Casting Die

3 times mentioned • Gohan Goku • 09 October 2017

Aluminium Die Casting Die

Using High Quality

43 times mentioned • Joey Yap • 07 August 2017

Using High Quality

|

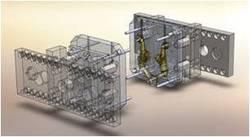

We are counted amongst trusted & renowned names in offering Die Casting Tooling Design Services. These services are offered by our team of experts using high quality machines. Our Die Casting Tooling Design Services are done according to the latest market techniques & methods. Our clients can avail these services at very affordable prices.

|

|

Pressure Die Casting

29 times mentioned • Bob Chen • 07 August 2017

Pressure Die Casting

|

This is the finest kind of die casting tool is being manufactured by our company. For production we are arranging the raw materials from some reliable vendors. Beside that we are maintaining international quality standards and both the things are ensuring our product quality. This Pressure Die Casting Tool is movable and very easy to use.

|

|

Everyone can have their own blog websites now. People use Invaber to blog their life, post their wishlists, post their preferences, share with others on Google. You also can discover more on what you blog. Invaber is sponsored by Microsoft.

|

|

Join Invaber |

|

|

What is Invaber? |

|

Lastest Business

|

|