Swipe left or right to close the panel.

×

Top 10 Most Related Posts

Best Review Based on Most Mentioned Phrase / Active User

The Most Widely Used

10 times mentioned • Mandy B B • 07 September 2017

The Most Widely Used

|

Aluminum and zinc alloys are the most widely used, and are followed by magnesium, zinc-aluminum (AZ) alloys, copper, tin and lead.

Zinc, lead and tin based alloys are classified as low melting point metals, all melting at less than 725oF (385oC). Zinc-aluminum (ZA) alloys have a slightly higher melting range of 800oF to 900oF (426oC to 482oC).

Aluminum and magnesium alloys are considered to be moderate melting point alloys, being cast in the 1150oF to 1300oF (621oC to 704oC) range. Copper alloys are considered to be high melting pint.

|

|

Low Melting Point

3 times mentioned • Nana Chin • 06 April 2016

Low Melting Point

|

Alffa Oleos (m) Sdn Bhd

We are offering margarine is a healthy, delicious and low cholesterol substitute to butter. We make available excellent quality margarine, made from natural and pure palm. Although, its taste differ from the butter but it is good for health and cost less.

costs less, easier to find, low melting point, no hydrogenation , 0% trans-fats, delicious, low cholesterol.

used for making delicious breakfast toasts, baking homemade cookies and other cookery purposes

|

|

Pacific Die Casting's

7 times mentioned • Edison Leo • 10 November 2017

Pacific Die Casting's

|

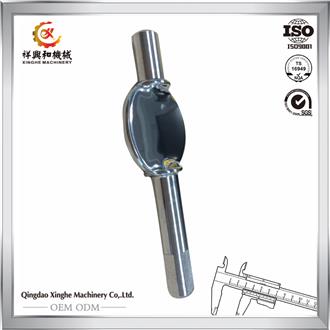

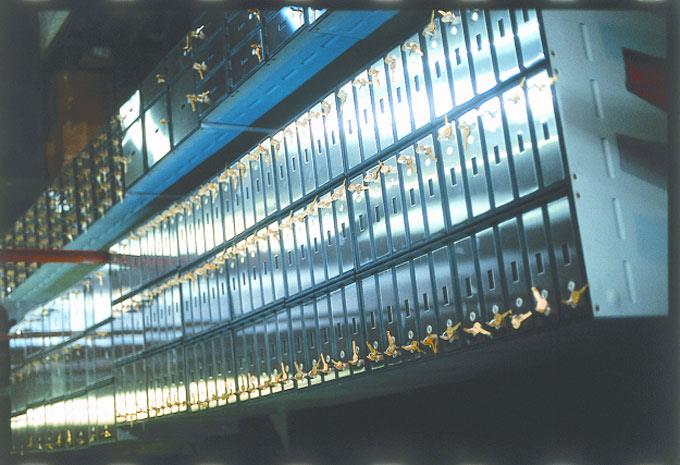

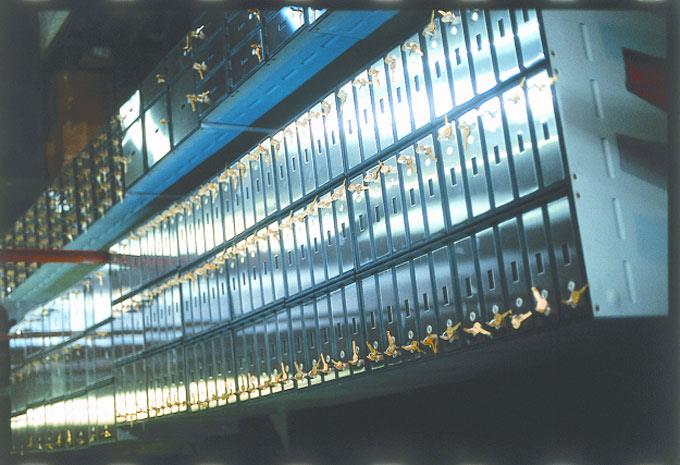

Save yourself the time and hassle. Pacific Die Casting's assembly staff can put parts together, so that you don't have to. There is no reason to get several different vendors involved. The picture above is an example of PDC's safe deposit box assembly line. Assembling safe deposit boxes is a daily occurrence at PDC, shipping more than a thousand cubic feet each day.

|

|

Pacific Die Casting's

7 times mentioned • Edison Leo • 10 November 2017

Pacific Die Casting's

|

Give your part that “final touch”. Pacific Die Casting's secondary department can handle many different requests. The secondary shop can accomplish these processes and more Anodizing, Painting, Powder coating, Plating, Media blasting, Vibratory finishing, Polishing, Brush Finishing, Impregnating.

|

|

Pacific Die Casting's

7 times mentioned • Edison Leo • 10 November 2017

Pacific Die Casting's

|

Mold Fabrication. In-house mold making, Lower mold quote with insert tooling, Reverse engineering, Tooling Modifications, Low cost conversion of existing mold to PDC machines. Pacific Die Casting's molds are built and engineered completely in-house allowing lower prices, faster turnaround, and a mold that best fit the customer's needs. Interfacing precision CNC and EDM machinery with the latest computer technology, the Mold Making Shop is at the forefront of modern die cast mold making.

|

|

Pacific Die Casting's

7 times mentioned • Edison Leo • 10 November 2017

Pacific Die Casting's

|

3D Printing. If you feel you need a physical 3D prototype before beginning the mold fabrication, Pacific Die Casting's new Rapid Prototyping System can quickly turn computer design data into a 3D prototype. Here is how it can help 3D physical prototype, Communicate and evaluate design concepts more efficiently, Collaborate with partners and vendors more effectively.

|

|

Pacific Die Casting's

7 times mentioned • Edison Leo • 10 November 2017

Pacific Die Casting's

|

If you feel you need a physical 3D prototype before beginning the mold fabrication, Pacific Die Casting's new Rapid Prototyping System can quickly turn computer design data into a 3D prototype. Here is how it can help 3D physical prototype in 24 hours, Communicate and evaluate design concepts more efficiently, Collaborate with partners and vendors more effectively, Rapid SLA prototyping machines, 3D prototype of automotive parts, SLA models with finished die casting parts.

|

|

Pacific Die Casting's

7 times mentioned • Edison Leo • 10 November 2017

Pacific Die Casting's

|

Zinc Die Casting. There are many advantages to running parts in zinc alloys and Pacific Die Casting's knowledgeable personnel can educate you on the benefits of casting in zinc. Zinc's physical properties make it an ideal alloy for engineers. Zinc also has a fine surface finish which makes it ideal for plating or powder coating. In addition, the ability of zinc to be cast with thin walls customers to design parts that could not typically be diecast in other alloys.

|

|

Pacific Die Casting

17 times mentioned • Edison Leo • 10 November 2017

Pacific Die Casting

|

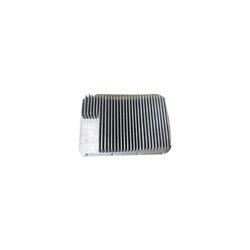

Aluminum Die Casting. Aluminum die casting has been a specialty of Pacific Die Casting since its founding. Pacific Die Casting has 24 aluminum die casting machines ranging from 250-1200 tons in our Commerce facility and 8 die cast machines ranging from 250-650 tons in our Tecate facility. Our 32 aluminum die cast machines give us the flexibility of running small and large parts in low and high volumes. Light weight, High dimensional stability for complex shapes and thin walls, Good corrosion resistance, Good mechanical properties, and etc.

|

|

Everyone can have their own blog websites now. People use Invaber to blog their life, post their wishlists, post their preferences, share with others on Google. You also can discover more on what you blog. Invaber is sponsored by Microsoft.

|

|

Join Invaber |

|

|

What is Invaber? |

|

Lastest Business

|

|