Swipe left or right to close the panel.

×

Friction Coefficient

Best Review Based on Most Mentioned Phrase / Active User

Pe Coated Steel Reinforced Hdpe

5 times mentioned • Jesper Wee • 20 January 2020

Pe Coated Steel Reinforced Hdpe

|

PE Coated Steel Reinforced HDPE Spiral Pipe. Metal Reinforced Spiral Corrugated Pipe. Long working life. Minimum 50 years life under nomal conditions. Hygiene. PE pipe are nontoxic, without the composition of heavy metal additives. No scale, not breeding germ, no second pollution to the potable water. High resistance to attack from various types of chemicals. No electrochemical corrosion. Smooth internal surface. Extremely low friction coefficient. Improved capability for media to pass through. Excellent abrasive resistance.

|

|

Long Service Life

38 times mentioned • Mandy B B • 12 May 2018

Long Service Life

|

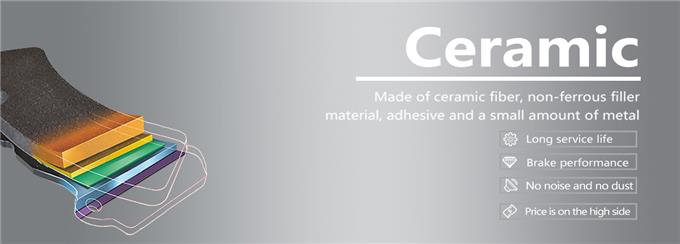

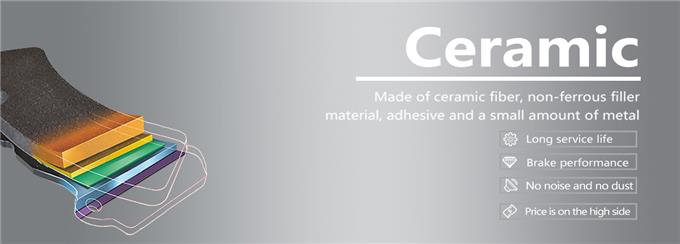

Ceramic. Made of ceramic fiber, non-ferrous filler material, adhesive and a small amount of metal. Long service life. Brake performance. No noise and no dust. Price is on the high side. Ceramic Brake pads. Friction coefficient 0.39, wear rate 0.2-0.4, service life: the Front is 40,000~50,000km, and the rear is 70,000~90,000km. No noise, no dust, less wear on the brake disc, smooth and uniform brake process, small thermal recession. Car products parts.

|

|

Longer Service Life

17 times mentioned • Joey Yap • 12 May 2018

Longer Service Life

|

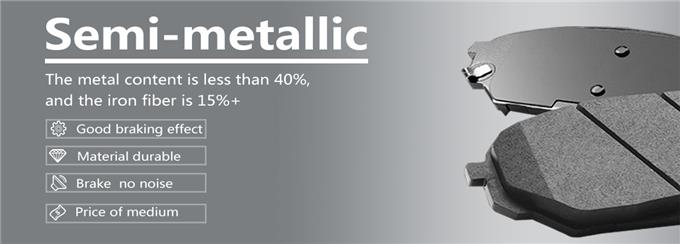

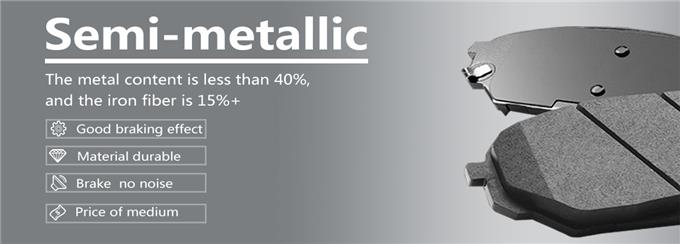

Semi-Metallic. The metal content is less than 40%, and the iron fiber is 15%+. Good braking effect. Material durable. Brake no noise. Price of medium. Semi-metallic Brake pads. The friction coefficient is 0.35, the wear rate is 0.2-0.45, and the service life: the front 30,000~50,000km, and the rear 60,000~ 80,000km. More stable performance, safer use, longer service life, but easy to produce noise, and wear on the brake disc. Car spare parts.

|

|

|

Everyone can have their own blog websites now. People use Invaber to blog their life, post their wishlists, post their preferences, share with others on Google. You also can discover more on what you blog. Invaber is sponsored by Microsoft.

|

|

Join Invaber |

|

|

What is Invaber? |

|

Lastest Business

|

|