Swipe left or right to close the panel.

×

Top 10 Most Related Posts

Best Review Based on Most Mentioned Phrase / Active User

Excellent Product Quality

3 times mentioned • Rayden Khoo • 31 July 2017

Excellent Product Quality

|

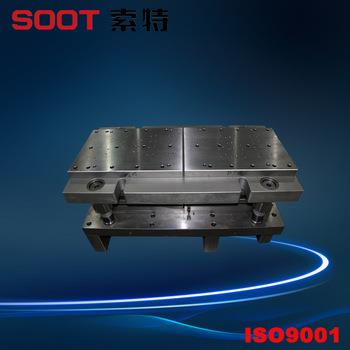

Precision progress metal stamping die maker in China. Customized stamping die sets for switch,socket,cir suit breaker and auto ect. Size: custom made by customers. Standard:National standard. Certification: ISO9001-2015. The main products of the company are miniature circuit breaker,mould-case circuit breaker,alternating current contractor,relay,wall switch and other stamping parts.We also provide customized products for the domestic and foreign customers and the received favorable comments due to excellent product quality and warm after-sales service.

|

|

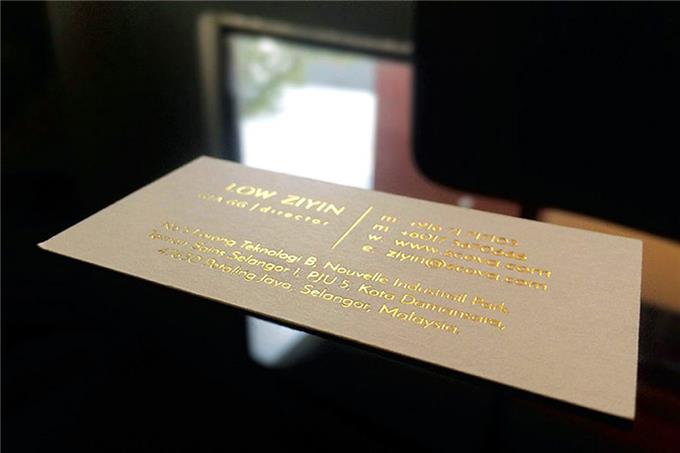

Extensive Experience Online Printing Services

4 times mentioned • Oscar Kingston • 21 March 2016

Extensive Experience Online Printing Services

|

DRB Printing Solutions is a valuable online print services that strives for excellent product quality and better printing experience through our most insightful service and smart internet platform.

DRB Printing Solutions was founded in 2008 as a printing supplier in Serdang, Selangor, Malaysia. With years of experience, we have quickly gained the trust of a wide range of clients by providing complete and customizable products and services at affordable price with guaranteed on time delivery.We are committed to help you achieve all of your advertising and marketing goals with our affordable and high quality services. With our innovative and extensive experience on online printing services, we are able to print anything you need, whenever you need it.

|

|

Best Quality Raw Materials Used

3 times mentioned • Leonardo Patel • 09 July 2019

Best Quality Raw Materials Used

|

Printed Flexible Laminated Packaging Material. Best quality packaging materials at most competitive price from renowned manufacturer and exporter from India. Produced in the advanced state of the art manufacturing facility. Best quality raw materials are used to ensure excellent product quality. Specially designed to meet specific requirement. Produced by highly trained and professional production and supporting staff.

|

|

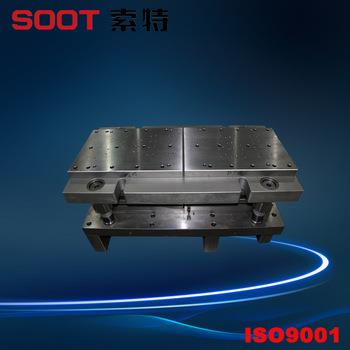

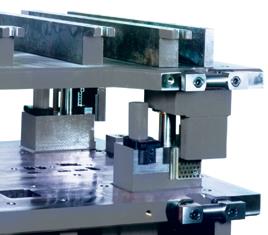

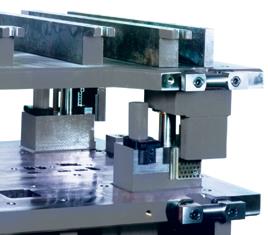

Metal Stamping Dies

12 times mentioned • Gohan Goku • 09 October 2017

Metal Stamping Dies

|

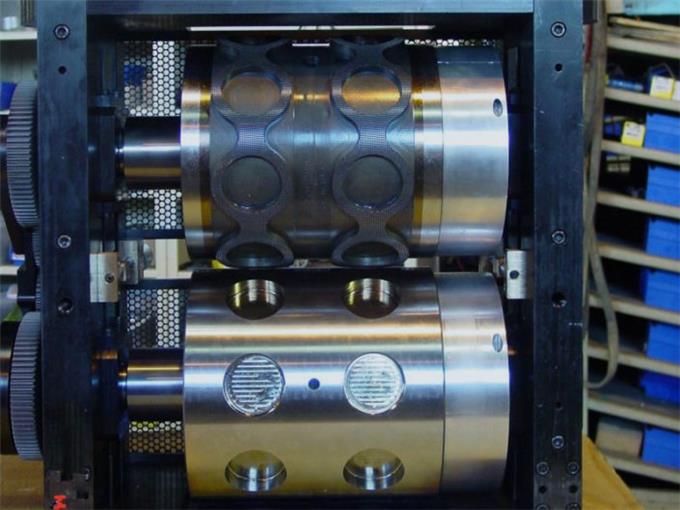

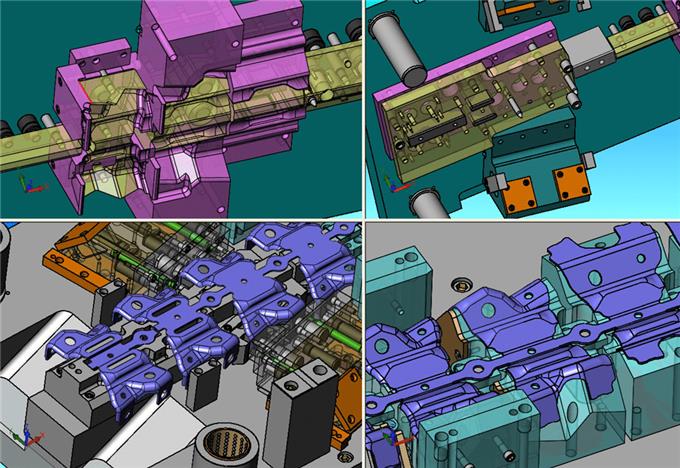

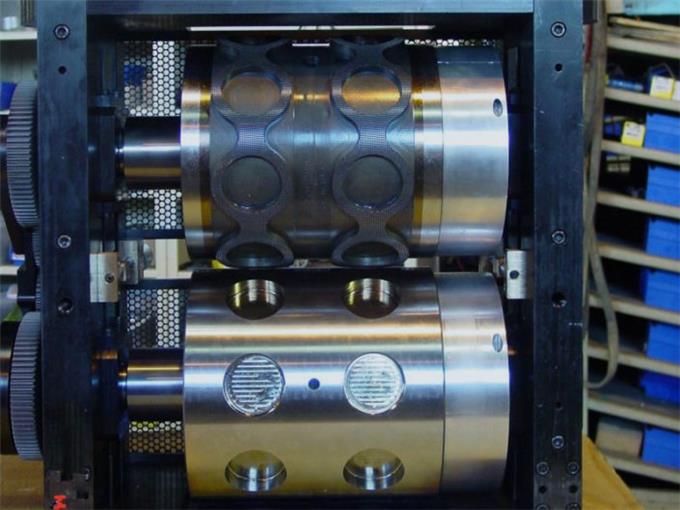

Die design Two Out Progressive Die for Industrial Application Hand transfer, progressive, drawing, forming, blanking and virtually any other metal stamping dies can be designed and built according to customer specifications. B&J International, LLC provides offshore metal stamping die design and fabrication services, for a wide range of industries and applications Die design

|

|

Wide Range Industries

12 times mentioned • Gohan Goku • 09 October 2017

Wide Range Industries

|

One Out Progressive Die for Agricultural Application B&J International, LLC provides offshore metal stamping die design and fabrication services, for a wide range of industries and applications. We maintain close communication with our suppliers in China Die design Our fabrication capabilities include building, finishing, inspection, and testing of the designed tooling.

|

|

Range Auto Parts

4 times mentioned • Mandy B B • 07 September 2017

Range Auto Parts

|

Stainless steel investment casting product. OEM/ODM Service die, molds, molding, molds, tooling CNC mahcining etc, made according to customers prints, drawings, specifications or samples. Production range auto parts, industrial metal parts, machine fitting and hardware parts. Available materials aluminum/zinc alloy, iron, steel alloy, plastic, brass, steel, stainless steel and plastic.

|

|

Service Provider

143 times mentioned • Rayden Khoo • 31 July 2017

Service Provider

|

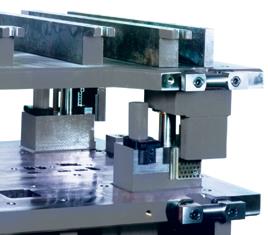

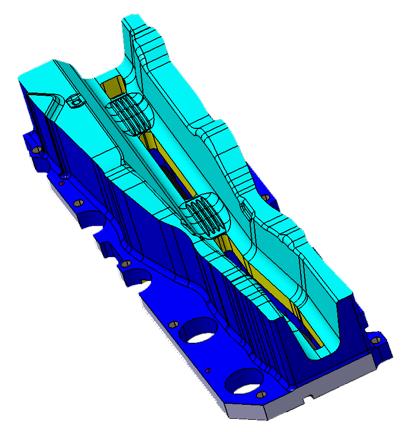

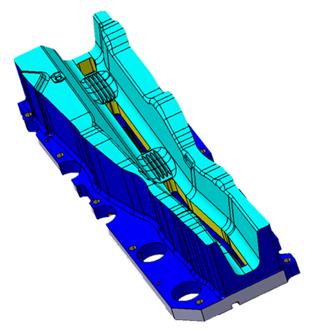

DIE DETAIL SOURCING. In an effort to help our customer increase their competitiveness and improve shop floor throughput, Die Cad supplies die details from best cost country (BCC) regions. All details are made to our customers exacting standards, with detailed inspection reports, and delivered to our customers shop in the North America. As a full service provider, Die Cad manages and takes responsibility for the entire process (sourcing, program management, logistics, duties, taxes) providing a seamless supply of die details to our customers.

|

|

Customer Service Team

13 times mentioned • Mr Chan • 19 August 2017

Customer Service Team

|

Anchor Danly has the largest die set manufacturing operations in North America. Custom Die Sets are available from 3 inches by 3 inches to 120 inches by 360 inches. Our customer service team can provide quick answers to your questions about die design, component usage and tooling needs.

|

|

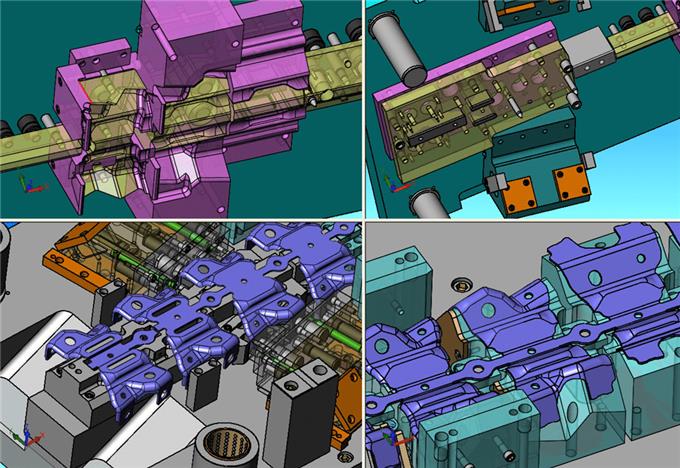

Die Design

87 times mentioned • Mandy B B • 30 July 2017

Die Design

|

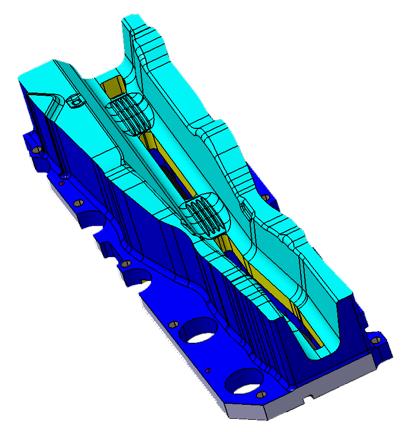

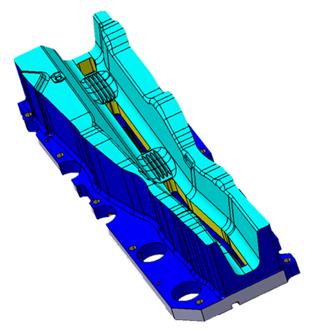

You can very easily and very quickly insert a plate or a sub-assembly and then adjust its dimensions. The plates can be named at this point and material type and heat treatment can also be specified at the time of insertion. It also acts as a Mate Manager so that you don't have to search the feature tree for mates. Component and sub-assembly insertion feature dedicated to the die design needs Customizable plates, Customizable die sets, Automatic mate management, Customizable material database and Customizable heat treat callouts.

|

|

Commonly Found

20 times mentioned • Mandy B B • 07 August 2017

Commonly Found

|

In practice, a critical part of die development is the configuration of the punches and dies. Not only the punches and dies are accommodated in the die holder, but also the other die elements. Modern forging dies are configured for various stations. This means additional forging, calibration, punching or trimming procedures are possible in the same operation (using four- or five-station die sets commonly found in operation today). Special dies, such as closing dies, can also be used. This significantly reduces production costs related to additional processing after the forging process.

|

|

Everyone can have their own blog websites now. People use Invaber to blog their life, post their wishlists, post their preferences, share with others on Google. You also can discover more on what you blog. Invaber is sponsored by Microsoft.

|

|

Join Invaber |

|

|

What is Invaber? |

|

Lastest Business

|

|