Swipe left or right to close the panel.

×

Top 10 Most Related Posts

Best Review Based on Most Mentioned Phrase / Active User

Kudo Turned Previously Researched Standards

5 times mentioned • Amelia Kate • 24 April 2020

Kudo Turned Previously Researched Standards

|

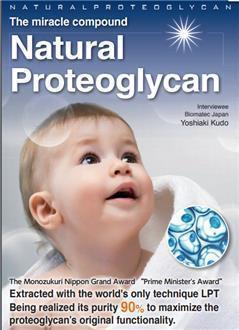

Succeeded in our dream to mass-produce this! We have also secured an international patent. The man who took up the challenge to mass-produce Proteoglycan was Mr.Yoshiaki Kudo of Biomatec Japan, our group company. Mr. Kudo turned previously researched standards of acid extraction on their heads and discovered alkaline extraction, thereby succeeding in extracting proteoglycan from the nasal cartilage of salmon. He reduced extraction times from 3 days to 1 1/2 hours, and improved overall extraction purity from 20% to 90%.

|

|

Kudo Turned Previously Researched Standards

5 times mentioned • Amelia Kate • 21 April 2020

Kudo Turned Previously Researched Standards

|

Proteoglycan. Mr. Kudo turned previously researched standards of acid extraction on their heads and discovered alkaline extraction, thereby succeeding in extracting Proteoglycan from the nasal cartilage of salmon.

He reduced extraction times from 3 days to 1 1/2 hours, and improved overall extraction purity from 20% to 90%.

Costs for this alkaline extraction method are only about 1/20th what they used to be. Overall this was a large leap forward in the practicality of Proteoglycan all at once.

|

|

Kudo Turned Previously Researched Standards

5 times mentioned • Amelia Kate • 09 April 2020

Kudo Turned Previously Researched Standards

|

Proteoglycan, the miracle compound. The alkaline extraction technology

that produces high-purity Proteoglycan. Mr. Kudo turned previously researched standards of acid extraction on their heads and discovered alkaline extraction, thereby succeeding in extracting Proteoglycan from the nasal cartilage of salmon. He reduced extraction times from 3 days to 1 1/2 hours, and improved overall extraction purity from 20% to 90%.

Costs for this alkaline extraction method are only about 1/20th what they used to be.

|

|

Kudo Turned Previously Researched Standards

5 times mentioned • Amelia Kate • 21 April 2020

Kudo Turned Previously Researched Standards

|

And now we've succeeded in our dream to mass produce this! We have also secured an International patent. The man who took up the challenge to mass produce Proteoglycan was Mr. Yoshiaki Kudo of Biomatec Japan our group Company.

Mr. Kudo turned previously researched standards of acid extraction on their head and discovered alkaline extraction, thereby succeeding in extracting Proteoglycans from the nasal cartilage of salmon. He reduced extraction time from 3 days to 1.5 hours, and improved overall extraction purity from 20% to 90%.

|

|

Biomatec Proteoglycan Produced Way Internationally

5 times mentioned • Aden Choo • 20 April 2020

Biomatec Proteoglycan Produced Way Internationally

|

He furthermore improved overall extraction purity from 20% to 90%. With costs for this alkaline extraction method being only about 1/20th what they used to be, commercial viability was suddenly much closer. The Biomatec proteoglycan produced this way is internationally patented and the only high-purity proteoglycan in the world derived by alkaline extraction LPT. Proteoglycan, the miracle compound that improves your quality of life.

|

|

Biomatec Proteoglycan Produced Way Internationally

5 times mentioned • Aden Choo • 24 April 2020

Biomatec Proteoglycan Produced Way Internationally

|

Succeeded in our dream to mass-produce this! We have also secured an international patent. Costs for this alkaline extraction method are only about 1/20th what they used to be. Overall this was a large leap forward in the practicality of Proteoglycan all at once. The Biomatec Proteoglycan produced this way is internationally patented and the only alkaline extracted high-purity Proteoglycan in the world.

|

|

Thanks Technological Advances Brought Research

4 times mentioned • Aden Choo • 21 April 2020

Thanks Technological Advances Brought Research

|

However, thanks to technological advances brought to us by research and development over many days and nights, we have arrived at an era where Proteoglycan can be available to everyone. Proteoglycan, the miracle compound. The alkaline extraction technology

that produces high-purity Proteoglycan

Producing such excellent Proteoglycan used to be quite expensive, and there was no mass-production, so it was not commonly used.

The man who took up the challenge to mass-produce Proteoglycan was Mr. Yoshiaki Kudo of Biomatec Japan, our group company.

|

|

Yoshiaki Kudo Biomatec Japan

5 times mentioned • Amelia Kate • 20 April 2020

Yoshiaki Kudo Biomatec Japan

|

The man who took up the challenge to mass-produce proteoglycan, which had proved impossible for researchers around the world was Mr. Yoshiaki Kudo of Biomatec Japan. Mr. Kudo upset the conventional wisdom of previously-researched acetic acid extraction techniques, and succeeded in extracting proteoglycan by LPT, a protein protection technique using alkaline extraction. He reduced extraction times that had taken 3 days with conventional acetic acid extraction techniques to just 1.5 hours.

|

|

Yoshiaki Kudo Biomatec Japan

5 times mentioned • Aden Choo • 09 April 2020

Yoshiaki Kudo Biomatec Japan

|

Proteoglycan, the miracle compound. The alkaline extraction technology

that produces high-purity Proteoglycan. Producing such excellent Proteoglycan used to be quite expensive, and there was no mass-production, so it was not commonly used.

The man who took up the challenge to mass-produce Proteoglycan was Mr. Yoshiaki Kudo of Biomatec Japan, our group company.

|

|

Reduced Maltose Starch Syrup

3 times mentioned • Aden Choo • 04 May 2020

Reduced Maltose Starch Syrup

|

Profil® (Proteoglycan). The edible film Profil® contains reduced maltose starch syrup, proteoglycan, pullulan, glycerin, glycerin fatty acid esters, cellulose. It's high purity proteoglycan extracting from the nasal cartilage of salmon by using alkaline extraction method. Proteoglycan is now one of the most noteworthy materials in the beauty and health care industry. It's outstanding effects are anti-inflammation, which suppresses inflammation in the body.

|

|

Everyone can have their own blog websites now. People use Invaber to blog their life, post their wishlists, post their preferences, share with others on Google. You also can discover more on what you blog. Invaber is sponsored by Microsoft.

|

|

Join Invaber |

|

|

What is Invaber? |

|

Lastest Business

|

|