Swipe left or right to close the panel.

×

Top 10 Most Related Posts

Best Review Based on Most Mentioned Phrase / Active User

Pe Coated Steel Reinforced Hdpe

5 times mentioned • Shawn Paul • 20 January 2020

Pe Coated Steel Reinforced Hdpe

|

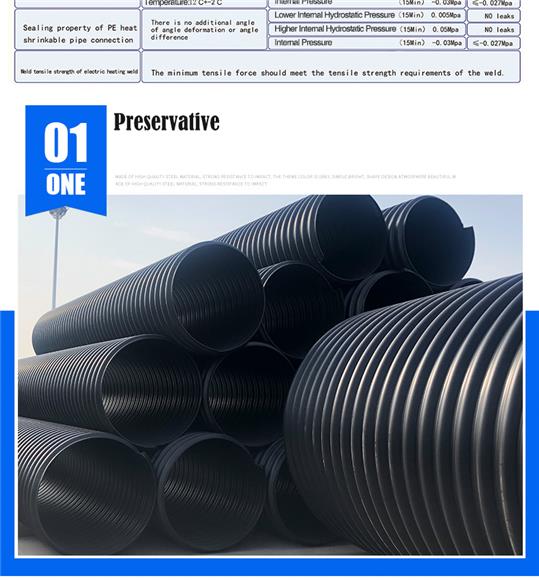

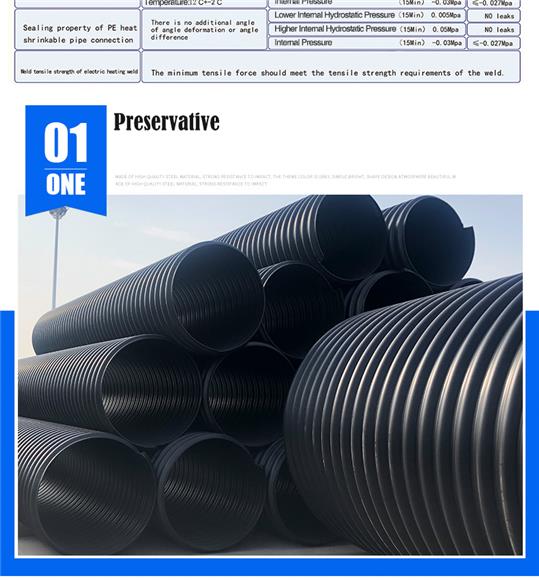

PE Coated Steel Reinforced HDPE Spiral Pipe. Metal Reinforced Spiral Corrugated Pipe. Good flexibility, high resistance to impact. Resistance to earthquake and twisting. Light weight, easy to transport, convenient installation. Unique electro fusion welding and butt welding make the joints stronger than the material, to guarantee a safe and reliable joint. Simple welding technique, convenient installation. Total cost is low for the installation. Polyethylene water pipes are produced in black, black with blue stripes and blue etc.

|

|

Pe Coated Steel Reinforced Hdpe

5 times mentioned • Jesper Wee • 20 January 2020

Pe Coated Steel Reinforced Hdpe

|

PE Coated Steel Reinforced HDPE Spiral Pipe. Metal Reinforced Spiral Corrugated Pipe. Applications Drinking water supply system, Nature Gas supply system, Food and chemical industry, Replacement of cement pipes and steel pipes, For Mine, argillaceous silt / mud transportation and Irrigation and garden green pipe networks and sewage treatment.

|

|

Pe Coated Steel Reinforced Hdpe

5 times mentioned • Jesper Wee • 20 January 2020

Pe Coated Steel Reinforced Hdpe

|

PE Coated Steel Reinforced HDPE Spiral Pipe. Metal Reinforced Spiral Corrugated Pipe. Long working life. Minimum 50 years life under nomal conditions. Hygiene. PE pipe are nontoxic, without the composition of heavy metal additives. No scale, not breeding germ, no second pollution to the potable water. High resistance to attack from various types of chemicals. No electrochemical corrosion. Smooth internal surface. Extremely low friction coefficient. Improved capability for media to pass through. Excellent abrasive resistance.

|

|

Pe Coated Steel Reinforced Hdpe

5 times mentioned • Shawn Paul • 20 January 2020

Pe Coated Steel Reinforced Hdpe

|

PE Coated Steel Reinforced HDPE Spiral Pipe. Metal Reinforced Spiral Corrugated Pipe. Corrosion Resistant, Impact Resistant and Easy to Install. Preservative. Easy to Install. Elevated Pipeline Laying. Road Construction. Residential Road Reconstruction. Pipeline Equipment Renovation. Mountain Water Pipe Laying. Road Reconstruction Project.

|

|

Reinforced Hdpe Spiral Pipe

6 times mentioned • Shawn Paul • 20 January 2020

Reinforced Hdpe Spiral Pipe

|

Steel belt reinforced HDPE spiral pipe. Non-toxic, apply to drinking water supply widely. Green Initiative, PE is a recycled material, environment friendly. Corrosion resistance: PE belongs to inert materials, can resistance to various chemical media. Long working life. Minimum 50 years life under normal conditions. Low system cost, less maintenance costs, reduce the cost for the project. Good flexibility, high resistance to impact. Resistance to earthquake and twisting.

|

|

Accurately Controlled Material Thickness Ensures

4 times mentioned • Jeff Lau • 20 April 2018

Accurately Controlled Material Thickness Ensures

|

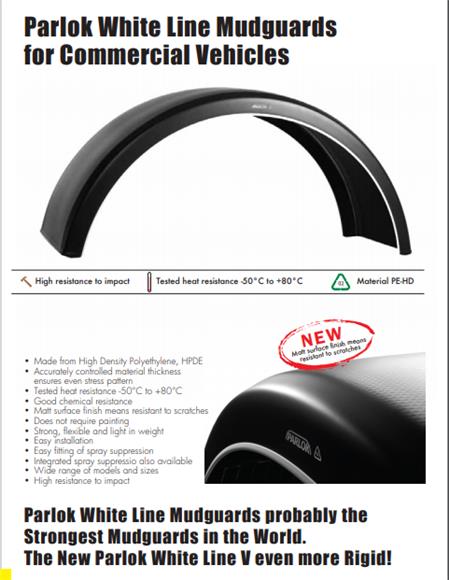

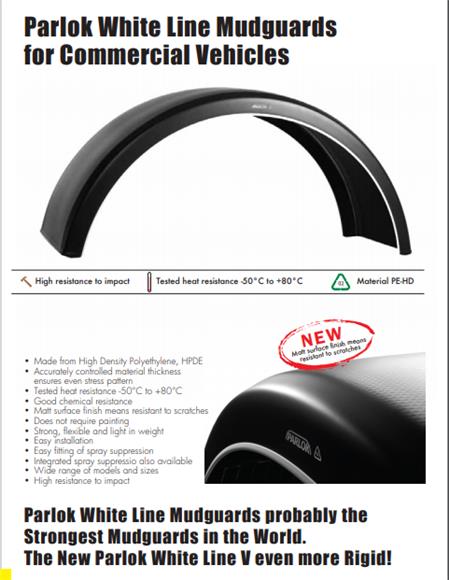

Parlok White Line Mudguards for Commercial Vehicles. High resistance to impact. Tested heat resistance -50°C to +80°C. Material PE-HD. Made from High Density Polyethylene, HPDE. Accurately controlled material thickness ensures even stress pattern. Good chemical resistance. Matt surface finish means resistant to scratches. Does not require painting. Strong, flexible and light in weight. Easy installation. Easy fitting of spray suppression. Integrated spray suppressio also available. Wide range of models and sizes. High resistance to impact.

|

|

Double Wall Corrugated Pipe

13 times mentioned • Jesper Wee • 17 January 2020

Double Wall Corrugated Pipe

|

900mm SN12.5 underground drain pipe china spiral pipe. Steel strip reinforced spiral corrugated (HDPE) polyethylene underground drain pipe (Abbreviation MRP) double wall corrugated pipe, steel reinforced winding pipe is a new type of buried plastic drainage tube developed in China in recent years. HDPE steel strip double wall corrugated pipe. Anticorrosive galvanized steel strap. Connect with heat shrinkable tape.

|

|

Specially Designed Profile Extrusion Process

8 times mentioned • Darius Ong • 14 September 2022

Specially Designed Profile Extrusion Process

|

HDPE Spiral Pipe is a common infrastructure product to be supplied in Malaysia. Spiral pipe is like an extruded profile strip that spirally wound over a mandrel. It was manufactured to this shape using a specially designed profile extrusion process. The cover on the edge is intertwined homogeneously while it is in the hot plastic state, creating a smooth inside surface. Spiral pipe system offers a wide range of fittings and manholes, which are also manufactured by specially designed profile-extrusion process. Rubbish chute Malaysia.

|

|

Specially Designed Profile Extrusion Process

8 times mentioned • Jesper Wee • 17 January 2020

Specially Designed Profile Extrusion Process

|

HDPE Spiral Pipe is a common infrastructure product to be supplied in Malaysia. Spiral pipe is like an extruded profile strip that spirally wound over a mandrel. It was manufactured to this shape using a specially designed profile extrusion process. The cover on the edge is intertwined homogeneously while it is in the hot plastic state, creating a smooth inside surface. Spiral pipe system offers a wide range of fittings and manholes. Rubbish Chute for High rise Buildings.

|

|

Specially Designed Profile Extrusion Process

8 times mentioned • Jesper Wee • 14 January 2020

Specially Designed Profile Extrusion Process

|

Spirolite HDPE Spiral Pipe is manufactured through a specially designed profile extrusion process where an extruded profile strip is spirally wound over a mandrel. Overlap on the edge is fused homogeneously together while it is in the hot plastic state, producing a smooth internal surface. Diameter ranges from: 300mm to 3,000mm. Sewerage, water treatment, drainage,culvert, float, rubbish chute, and formwork for slotted drain.

|

|

Everyone can have their own blog websites now. People use Invaber to blog their life, post their wishlists, post their preferences, share with others on Google. You also can discover more on what you blog. Invaber is sponsored by Microsoft.

|

|

Join Invaber |

|

|

What is Invaber? |

|

Lastest Business

|

|